Post Moulding Services

Injection moulding is not always a fully automated process as machine operators may be required at the m/c and operations may have to be completed outside of the production cycle.

At PRISTINE MEDICURE, we realise that customers can require additional services to produce their finished components. This can be to reduce initial cost to meet a particular budget or to achieve a feature which cannot be completed in standard tool configurations.

In response to this increasing requirement we are able to provide a range of in-house post moulding services:

Packing

Bespoke packaging procedures are followed to customer requirements in our dedicated packing department.

Finishing

For the removal of surplus material by hand or linishing techniques to achieve the final finish required.

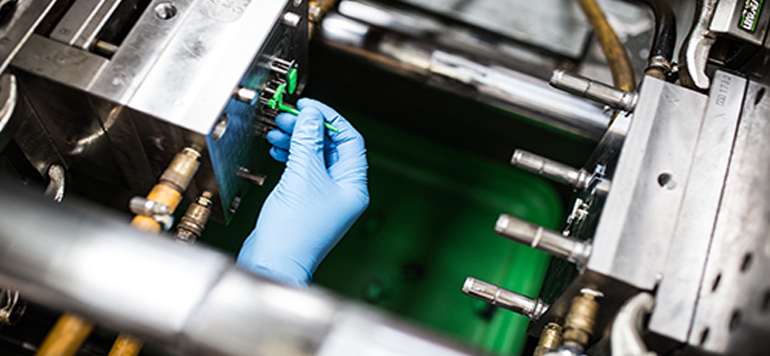

Light Assembly

Our team are able to carry out light assembly duties when a finished component is made up of more than one part that need to be fitted together.